Related Resources: calculators

Arc Beam Spring Design Formulae and Calculator

Spring Design and Engineering Equations and Calculators

Arc Beam Spring Design Formula and Calculator

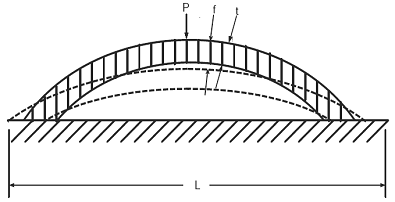

Beam springs are usually rectangular in shape and formed into an arc as shown in Figure 1.

Figure 1 - Typical Arc Beam Spring

Preview: Arc Beam Spring Design Calculator

The bending stress for Arc Beam Spring can be determined as follows:

Eq. 1

S = ( 6 · EM · f · t ) / ( L2 )

Where:

S = Bending stress, lbs/in2, (N.mm2)

EM = Modulus of Elasticity, lbs/in2, (N.mm2)

f = deflection, in (mm)

t = thickness,

in (mm)

L = Active spring length, in (mm)

The failure rate of a Arc Beam Spring is determined using the following equation:

Eq. 2

λSP = λSP,B · ( S / Ts )3 · Ccs · CR · CM

A generalized equation that adjusts the base failure rate of a beam spring considering anticipated operating conditions can be established:

Eq. 3

λSP = λSP,B · CE · Ct · CL · Cf · CY · CCS · CR · CM

Where:

λSP = Failure rate of torsion spring, failures/million hours

λSP,B = Base failure rate for torsion spring, 14.3 failures/million hours

CE = Multiplying factor which considers the effect of the material elasticity modulus on the base failure rate

Eq. 4

CE = ( EM / 28.5 x 106 )3

Ct = Multiplying factor which considers the effect of the material

thickness on the base failure rate

Eq. 5

Ct = ( t / 0.025 )3

CL = Multiplying factor which considers the effect of washer diameter

on the base failure rate

Eq. 6

CL = ( 1.20 / L )6

CY = Multiplying factor which considers the effect of material tensile strength on the base failure rate

Eq. 7

CY = ( 190 x 103 / Ts )3

Ts = Tensile Strength, lbs/in2, (N/mm2)

Cf = Multiplying factor which considers the effect of washer deflection

on the base failure rate

Eq. 8

Cf = ( f / 0.055 )3

CCS = Multiplying factor which considers the effect of a corrosive environment on the base failure rate

Eq. 9a

CCS = 0.100 If CR ≤ cycles/min

Eq. 9b

CCS = CR / 300 ) For 30 cycles/min < CR ≤ 300 cycles min,

Eq. 9c

CCS = ( CR / 300 )3 ForCR > 300 cycles/min,

CR = Multiplying factor which considers the effect of a corrosive environment on the base failure rate

Eq. 10

CR = 1.0 unless or greater than 1.0 with user's experience with the spring and the operating environment.

CM =

Multiplying factor which considers the effect of the

manufacturing process on the base failure rate

Eq. 11

CM = 1.0 a higher value for the multiplying factor is used based on

previous experience with the manufacturer.

Reference:

Handbook of of Reliability Predictions Procedure for Mechanical Equipment

Logistics Technology Support

CARDEROCKDIV, NSWC-11

2011

Related

- Cantilever Beam Spring Design Formula and Calculator

- Belleville Washer Design Formulae and Calculator

- Wave Washer Design Formula and Calculator

- Curved Washer Design Formula and Calculator

- Torsion Spring Design Formula and Calculator

- Torsion Spring Arc Length Formula and Calculator

- Torsion Spring Calculator

- Design Equations of Belleville Washer Springs

- Belleville Spring Washer Equation and Calculator

- Torsion Applied Spring Stiffness Constant Equations and Calculator

- Coil-Diameter Tolerances of Torsion Springs Specifications

- Morrison's Spring Tables Design Reference Premium Membership Required to view Document/Book

- Typical Modulus of Elasticity of Spring Materials used in Torsion and Tension

- Mass Spring Simulator and Calculator

- Spring Properties and Material

- Springs Made From Rectangular Section Bar Steel Design and Calculations

- Stresses in Helical Springs Produced by Shocks Formulas and Calculator