Related Resources: management

Engineering Design Manufacturing Costs Calculator

Detailed Estimating Engineering Design and Manufacturing Costs Equations and Calculator

The resources (skills, calendar time, and labor-hours) required to prepare a cost estimate depend on a number of factors. One factor is the estimating method utilized. Another is the level of technology or state of the art involved in the job or task being estimated. A rule of thumb can be utilized to develop a rough idea of the estimating time required. The calendar time required to develop an accurate and credible estimate is usually about 8% of the calendar time required to accomplish a task involving existing technology and 18% for a task involving a high technology (i.e., nuclear plant construction, aerospace projects).

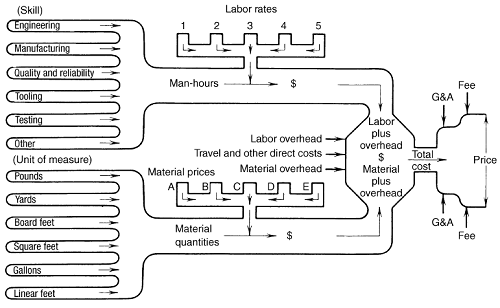

Anatomy of an Estimate Flow Chart

Preview: Detailed Estimating Engineering Design and Manufacturing Costs Calculator (Membership Required: Premium).

| T = | { [ EH x ER ) x ( 1 + EO ) ] + [ ( Mh x MR ) x ( 1 + MO ) ] + [ ( TOH x TOR ) |

| x ( 1 + TOo ) ] + [ ( QH x WR ) x ( 1 + QO ) ] + [ ( TEH + TER ) x ( 1 + TEO ) ] | |

| + [ ( OH x OR ) x ( 1 + QO ) ] + SD + SO + [ MD x ( 1 + MOH ) ] | |

| + TD + CD + ODD } x {GA + 1.00 } x { F + 1.00 } |

Where:

T = total cost

EH = engineering labor hours

ER = engineering composite labor rate in dollars per hour

EO = engineering overhead rate in decimal form (i.e., 1.15 = 115%)

MH= manufacturing labor hours

MR = manufacturing composite labor rate in dollars per hour

MO = manufacturing overhead rate in decimal form

TOH = tooling labor hours

TOR = tooling composite labor rate in dollars per hour

TOO = tooling overhead in decimal form

QH= quality, reliability, and safety labor hours

QR = quality, reliability, and safety composite labor rate in dollars per hour

QO = quality, reliability, and safety overhead rate in decimal form

TEH = testing labor hours

TER = testing composite labor rate in dollars per hour

TEO = testing overhead rate in decimal form

OH = other labor hours

OR = labor rate for other hours category in dollars per hour

OO = overhead rate for the hours category in decimal form

SD = major subcontract dollar

SO = other subcontract dollars

MD = material dollars

MOH = material overhead in decimal form (10% = 0.10)

TD = travel dollars

CD = computer dollars

ODD = other direct dollars

GA = general and administrative expense in decimal form (25% = 0.25)

F = fee in decimal form (0.10 = 10%)

Note that the largest percentage of the required estimating time is for defining the output. This area is most important because it establishes a good basis for estimate credibility and accuracy, as well as making it easier for the estimator to develop supportable labor-hour and material estimates. These percentages also assume that the individuals who are going to perform the task or who have intimate working knowledge of the task are going to assist in estimate preparation. Hence the skill mix for estimating is very similar to the skill mix required for actually performing the task.