Related Resources: material science

Stress Concentration Factors for Flat Plates and Cylinders

Strength of Materials

Beam Deflection and Stress

Stress Concentration Factors for Flat Plates and Cylinders :

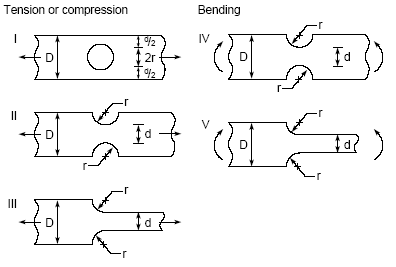

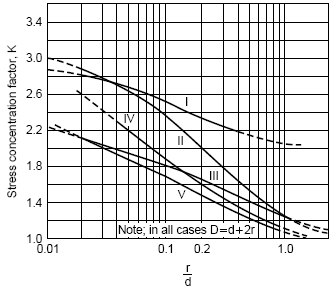

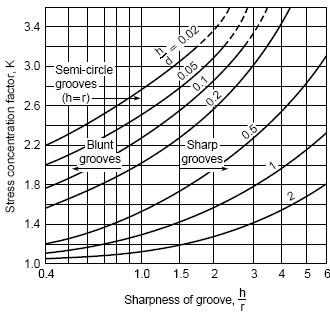

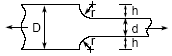

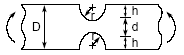

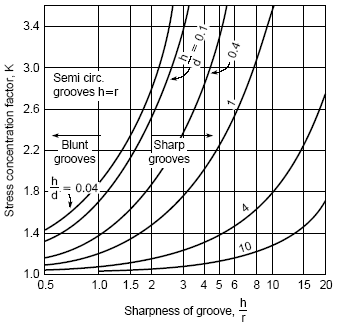

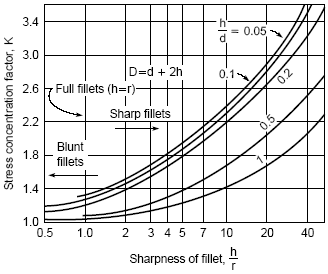

In a structure or machine part having a notch or any abrupt change in cross section, the maximum stress will occur at this location and will be greater than the stress calculated by elementary formulas based upon simplified assumptions as to the stress distribution. The ratio of this maximum stress to the nominal stress (calculated by the elementary formulas) is the stress-concentration factor Kt . This is a constant for the particular geometry and is independent of the material, provided it is isotropic. The stress-concentration factor may be determined experimentally or, in some cases, theoretically from the mathematical theory of elasticity.

The factors shown on this webpage were determined from both photo elastic tests and the theory of elasticity. Stress concentration will cause failure of brittle materials if the concentrated stress is larger than the ultimate strength of the material. In ductile materials, concentrated stresses higher than the yield strength will generally cause local plastic deformation and redistribution of stresses (rendering them more uniform). On the other hand, even with ductile materials areas of stress concentration are possible sites for fatigue if the component is cyclically loaded.

Related:

- Stress concentration factors for shafts and cylinders

- Stress concentration fundamentals

- Local Stress-Strain Fatigue Method ( ε-N )

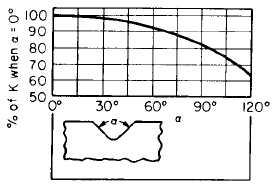

Flat plate with semicircular fillets and grooves or with holes. I, II, and III are in tension or compression; IV and V are in bending.

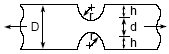

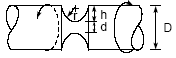

Flat plate stress concentration factors with grooves, in tension.

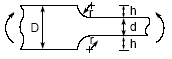

Flat plate stress concentration factors with fillets, in tension.

Flat plate stress concentration factors with grooves, in bending.

Flat plate stress concentration factors with fillets, in bending.

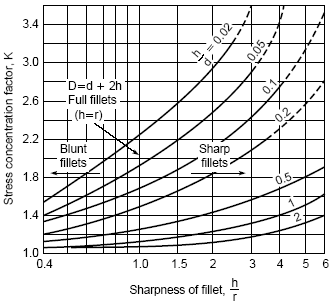

Flat plate stress concentration factors with angular notch, in tension or bending.

Flat plate stress concentration factors with angular notch, in tension or bending.

Filleted shaft stress concentration factors in torsion.

References:

Marks Standard Handbook for Mechanical Engineers

Contributed by: M.K Guler, Boeing