Related Resources: calculators

Tire Traction Force Equation and Calculator

Power Transmission Design and Engineering

Engineering and Design Applications

Tire Traction Force Equation and Calculator

Related:

Tire Traction Breakaway Equation and Calculator

Tire Traction Force, or tractive force, is the force used to generate motion between a car or truck and the road or tangential surface.

Tire Traction can also refer to the maximum tractive force between a body and a surface, as limited by available friction; when this is the case, traction is often expressed as the ratio of the maximum tractive force to the normal force and is termed the coefficient of traction.

Applied tractive force based on engine torque equation:

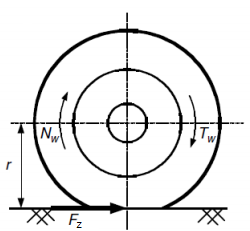

Fz = [ 2 · π · Mmot · η · iG · iv · iA ] / U

Where ,

Fz = Tractive force in N

Mmot = Engine torque in Nm

η = Overall efficiency of power train (see table below)

iG = Transmission ratio)

iv = Driving axle ratio

iA = Final drive atio of the driven axle(s)

U = Tire rolling Circumference = 2 · π · r in m

r = Tire radius in m

Overall Efficiency in the Drive Train

| Number of Driven Axles | η |

| One axle | 0.95 |

| Two Axles | 0.90 |

| Three axles | 0.85 |

| Four axles | 0.80 |

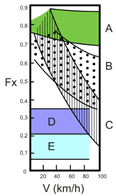

Coefficient of traction : The coefficient of traction is defined as the usable force for traction divided by the weight on the running gear (wheels, tracks etc.).

usable traction = coefficient of traction x normal force

Factors affecting coefficient of traction

Tire traction between two surfaces depends on several factors:

- Material composition of each surface.

- Macroscopic and microscopic shape ( texture ; macrotexture and microtexture )

- Normal force pressing contact surfaces together.

- Contaminants at the material boundary including lubricants and adhesives.

- Relative motion of tractive surfaces - a sliding object (one in kinetic friction) has less traction than a non-sliding object (one in static friction).

- Direction of traction relative to some coordinate system - e.g., the available traction of a tire often differs between cornering, accelerating, and braking.

- For low-friction surfaces, such as off-road or ice, traction can be increased by using traction devices that partially penetrate the surface; these devices use the shear strength of the underlying surface rather than relying solely on dry friction (e.g., aggressive off-road tread or snow chains )....

The maximum permissible traction or force that can be applied to the wheels is governed by two things: the weight of the vehicle and the adhesion coefficient between the tire and the road surface.

More the weight and the adhesion coefficient, more amount of tractive force can be applied to the wheels without causing slips between the tires and road.

In the design of wheeled or tracked vehicles, high traction between wheel and ground is more desirable than low traction, as it allows for higher acceleration (including cornering and braking) without wheel slippage. One notable exception is in the motorsport technique of drifting , in which rear-wheel traction is purposely lost during high speed cornering.

In some applications, there is a complicated set of trade-offs in choosing materials. For example, soft rubbers often provide better traction but also wear faster and have higher losses when flexed—thus reducing fuel and rolling efficiency.

The traction of trucks, agricultural tractors, wheeled military vehicles, etc. when driving on soft and/or slippery ground can be improved significantly by use of Tire Pressure Control Systems (TPCS). A TPCS makes it possible to reduce and later restore the tire pressure during continuous vehicle operation. Increasing traction by use of a TPCS also reduces tire wear and ride vibration.

References

Kelly Bramble, ASME-S-GDTP, A&P, Engineers Edge, LLC

Tushar Sirdeshmukh , B.Tech Mechanical Engineering, Visvesvaraya National Institute of Technology,Nagpur