Related Resources: calculators

Helix Gearing with Shafts at Any Angle Center Distance Approximate Design Equations and Calculator

Machine Design and Engineering

Mechanical Gear Design and Engineering

Helix Gearing with Shafts at Any Angle, Center Distance Approximate Design Equations and Calculator

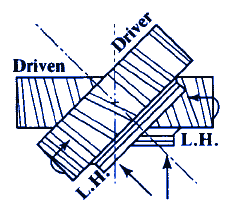

The sum of the helix angles of the two gears equals the shaft angle, and the gears are of the same hand, if each angle is less than the shaft angle. The difference between the helix angles equals the shaft angle, and the gears are of opposite hand, if either angle is greater than the shaft angle.

The sum of the helix angles of the two gears equals the shaft angle, and the gears are of the same hand, if each angle is less than the shaft angle. The difference between the helix angles equals the shaft angle, and the gears are of opposite hand, if either angle is greater than the shaft angle.

Related:

- Helical Gears Shafts Parallel Center Distance Exact Design Equations and Calculator

- Helical Gears Shafts Parallel Center Distance Approximate Design Equations and Calculator

- Helical Gears Shafts at Right Angles Approximate Design Equations and Calculator

- Gears Shafts Right Angles Exact Helix Design Equations and Calculator

Preview Helical Gears Shafts at Any Angle Design Calculator

Design variables you should know:

- Position of gear having right- or left-hand helix depending on rotation and direction in which thrust is to be received,

- Center distance between gear Ca

- Normal diamtral pitch (pitvh of cutter) Pn

- Angle of helix, gear α

- Angle of helix, pinion β

Ratio of gear to pinion

R = N / n

Number of teeth in pinion nearest calculation for any angle

n = ( 2 Ca Pn cos α cos β ) / ( R cos β + cos α )

Number of teeth in pinion nearest calculation for when both angles are equal

n = ( 2 Ca Pn cos α ) / ( R + 1 )Number of teeth in gear

N = Rn

Pitch diameter of gear

D = N / ( Pn cos α )

Pitch diameter of pinion

d = n / ( Pn cos β )

Outside diameter of gear

O = D + 2 / Pn

Outside diameter of pinion

o = d + 2 / Pn

Number of teeth marked on cutter for gear

T = N / ( cos3α )

Number of teeth marked on cutter for pinion

t = n / ( cos3α )

Lead angle of helix on gear

L = π D cot α

Lead angle on pinion

l = π d cot β

Actual center distance between gear and pinion

C = ( D + d ) / 2

Where:

C = approximate center distance (in, mm),

Pn = normal diametral pitch (in, mm),

N = number of teeth in large gear,

n = number of teeth in small gear,

α = angle of gear helix (deg),

β = angle of pinion helix (deg),

R = ratio of gear to pinion,

L = lead of helix on large gear (in, mm),

l = lead of helix on pinion (in, mm).

References:

Machinerys Handbook, 29th Edition