Related Resources: pressure-vessel

Stress in Cone or Conical Section Seam Equations and Calculator

Structural Design and Analysis

Pressure Vessel Design and Engineering

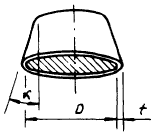

Stress in Cone or Conical Section Seam Equation and Calculator

The stress in the girth seam will govern only when the circumferential join efficiency is less than one - half the longitudinal joint efficiency, or when the internal pressure additional loadings (wind load, reaction of saddles) are causing longitudinal bending or tension . The reason for it is that the stress arising in the girth seam pound per square inch is one - half of the stress in the longitudinal seam.

ALL calculators require a Premium Membership

Preview

Stress in Cone or Conical Section Seam Calculator:

Required minimum wall thickness

t = [ P (D + 2CA) ] / ( 2 cosα (SE - 0.6P) + CA

Maximum allowable working pressure

P = 2SEta cosα / ( D + 1.2 ta cosα )

Where:

P = Design pressure or max. allowable working pressure, psi

S = Rated stress value of the material

E = Weld Joint efficiency

R = Inside radius, inches

D = Inside diameter of vessel , inches

α = Angle in Degrees

t = Thickness of shell (wall), inches

ta = Wall thickness used in actual design, inches

CA = Corrosion allowance, inches

- The half apex angle, α not greater than 30° .

Example:

Given:

P = 100 psi design pressure

S = 17,500 psi stress value of SA 515-70 plate @ 650°F

E = 0.85, efficiency of of spot welded joints

D = 96 inches

R = 48 inches

α = 30°

CA = 0.125 in

Shell thickness requirements:

t = ( 100 psi x 96.25 in.) / ( 2 x 0.866 x (17,500 psi x 0.850 - 0.6 x 100 psi) + 0.125 in.

t = 0.500 in.

Probably use 0.500 in. plate for design = ta

Maximum working pressure

ta = ( 2 x 17,500 psi x 0.85 x 0.500 in x 0.866) / ( 96.00 in + 1.2 x 0.500in x 0.866)

ta = 133 psi