Related Resources: pressure-vessel

Boiler Tubes Thickness Pressure Equation and Calculator

ASME Pressure Vessel Design and Engineering

ASME SECTION I – Boiler Tubes up to and including 5 inches O.D. (125 mm):

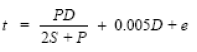

The minimum required thickness, according to ASME paragraph PG-27.2.1, use equation below:

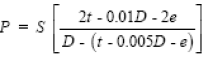

To calculate the Maximum Allowable Working Pressure (MAWP):

Where:

t = Minimum Design Wall Thickness (in);

P = Design Pressure (psi);

D = Tube Outside Diameter (in);

e = Thickness Factor (0.04 for expanded tubes; 0 = for strength welded tubes);

S = Maximum Allowable Stress According to ASME Section II.

Example - Boiler Tube:

Calculate the minimum required wall thickness of a water tube boiler 2.75 in O.D., strength welded (E, or, e = 0) into place in a boiler. The tube has an average wall temperature of 650°F. The Maximum Allowable Working Pressure (MAWP) is 580 psi gauge. Material is carbon steel SA-192. Note: Before starting calculations check the correct stress table in ASME Section II, Table 1A:

Consider SA-192 = 11,800 psi – allowable stress – Div. 1.

Solution:

For tubing up to and including 5 in O.D., use equation above.

P = [580 psi]

D = [2.75 in]

e = 0 (strength welded)

S = [11,800 psi] at [650°F])

![]()

Note: Where the manufacturing processes produce only standard plate thickness, so should be used 1/8 in (3.2 mm) minimum.

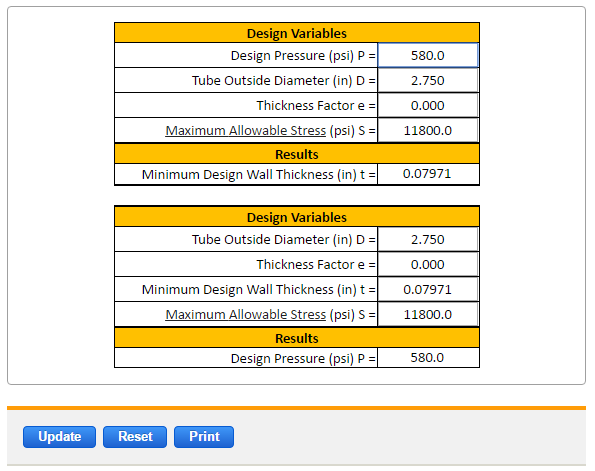

Calculator Preview