Related Resources: calculators

Thickness of Pipe Blanks Caps Formula and Calculator

Flat Plates Stress, Deflection Equations and Calculators

Design Thickness of Pipe Blanks Caps Formula and Calculator per. ASME B31.5

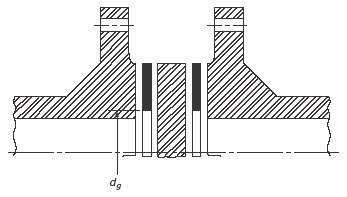

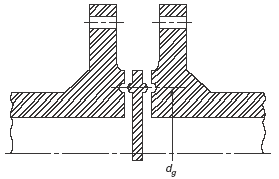

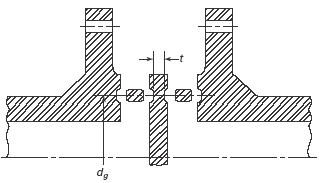

The pressure design thickness of permanent blanks (see Fig. 1, 2 and 3) shall be calculated in accordance with eqs. (1) and (2).

Preview: Design Thickness of Pipe Blanks Calculator

Eq. 1

t = dg · [ 3 · P / ( 16 · S ) ]1/2

Eq. 2

tm = t + c

Eq. 3

P = ( t / dg )2 (16 · S ) / 3

Where:

t = pressure design thickness, in. (mm).

tm = minimum required blind flange thickness, satisfying requirements for pressure and mechanical, corrosion, and erosion allowances, in. (mm)

dg = inside diameter of gasket for raised or flat (plain) face flanges, or the gasket pitch diameter for retained gasketed flanges, in. (mm).

P = internal design pressure , psi (kPa), or external design pressure , psi (kPa).

S = applicable allowable stress, psi (MPa).

c = sum of the mechanical, corrosion, and erosion allowances, in. (mm)

ASME Blank Type 1

ASME Blank Type 2

ASME Blank Type 3

Related:

- Pressure Vessel Design Formula and Calculators Resources

- Thick Walled Cylinder Stress Pressure Vessel Equations and Calculator

- Strength and Mechanics of Materials

- Pressure Vessel Wall Thickness with Internal Pressure Applied Calculator

- Pressure Vessel External Pressure Calculations

- Flat Circular Head Welded with Internal or External Pressure Equation and Calculator

- Pressure Vessel Flanged Dish Head Design Tool Calculator

Reference:

- ASME Code for Pressure Piping, B31.5, Refrigeration Piping and Heat Transfer Components, Paragraph 504.5.3