Related Resources: calculators

Step Thrust Plate Bearing Design Equation and Calculator

Machine Design Applications

Bearing Engineering and Design

Step Thrust Plate Bearing Design Equation and Calculator:

Related:

Flat Thrust Plate Bearing Design Formulas and Calculator

Step Thrust Plate Bearing

Preview: Step Thrust Plate Bearing Design Calculator

|

Thrust Bearing Typical Loads

|

||

|

Surface

|

Loads

Lbs/in2 |

Max Loads

Lbs/in2 |

|

Parallel surface

|

< 75

|

< 150

|

|

Step Surface

|

200

|

500

|

|

Tapered Land Surface

|

200

|

500

|

|

Tilting Pad Surface

|

200

|

500

|

Reproduced with permission from Wilcock and Booser, Bearing Design and Applications, McGraw-Hill Book Co., Copyright © 1957.

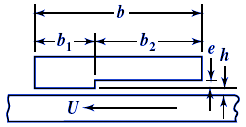

General Design Parameters: Recommended optimum proportions, a = b, b2 = 1.2b1, and e = 0.7h.

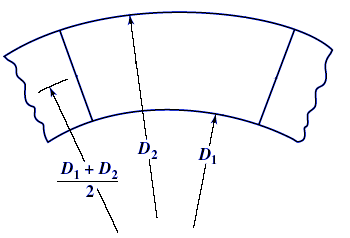

External diameter formula:

D2 = ( ( 4 W ) / ( ( π Kg p ) + D12 )1/2

Where:

W = applied load, pounds

Kg = fraction of circumference occupied by pads; usually, 0.8

p = bearing unit load, psi

Radial pad width, given in inches

a = (1/2) ( D2 + D1 )

Number of bearing pads, i. Assume that the oil groove width, s = 0.062 inch is minimum

i = B / ( a + s ) = nearest even number

i as the nearest even number to that calculated.

Length of bearing pad given in inches

b = B / i - s

Pitch line velocity, given in fpm

U = ( B N ) / 12

where, N - rpm

Film thickness, given in inches

h = [ ( 2.09 x 10-9 i a 3 U Z ) / W ]0.5

Depth of step, given in inches

e = 0.7 h

Friction power loss, given in HP

Pf = ( 7.35 x 10-13 i a2 U2 Z ) / h

Pad step length, distance is on the pitch line, from the leading edge of the pad to the step. Given in inches.

b2 = ( 1.2 b ) / 2.2

Hydrodynamic oil flow, given in gpm

Q = 6.65 x 10-4 i a h U

Temperature rise, given in degrees F

Δt = ( 42.4 Pf ) / ( c Q )

Should temperature rise to be excessive, this is an indication that the flow is insufficient

Notation:

a = radial width of pad, inches

b = circumferential length of pad at pitch line, inches

b2 = pad step length

B = circumference of pitch circle, inches

c = specific heat of oil, Btu/gal/°F

D = diameter, inches

e = depth of step, inch

f = coefficient of friction

g = depth of 45° chamfer, inches

h = film thickness, inch

i = number of pads

J = power loss coefficient

K = film thickness factor

Kg = fraction of circumference occupied by the pads; usually, 0.8

l = length of chamfer, inches

M = horsepower per square inch

N = revolutions per minute

O = operating number

p = bearing unit load, psi

ps = oil-supply pressure, psi

Pf = friction horsepower

Q = total flow, gpm

Qc = required flow per chamfer, gpm

Qoc = uncorrected required flow per chamfer, gpm

QF = film flow, gpm

s = oil-groove width

∆t = temperature rise, °F

U = velocity, feet per minute

V = effective width-to-length ratio for one pad

W = applied load, pounds

Yg = oil-flow factor

Yl = leakage factor

YS = shape factor

Z = viscosity, centipoises

α = dimensionless film-thickness factor

δ = taper

ξ = kinetic energy correction factor

References:

- Machinery's Handbook, 29th Edition

- Understanding Journal Bearings, Malcolm E. Leader, P.E. Applied Machinery Dynamics Co.

- Theory and Practice of Lubrication for Engineers by Dudley D. Fuller, Wiley and Sons, 1984, ISBN 0- 471-04703-1

- Bearing Design and Application by Donald F. Wilcock and E. Richard Booser, McGraw Hill, 1957, 195, LC number 56-9641