Related Resources: calculators

Abrasive Water Jet Material Rate Equation and Calculator

Manufacturing, Design and Engineering

Abrasive Water Jet Machining Material Rate Equation and Calculator

The physics,

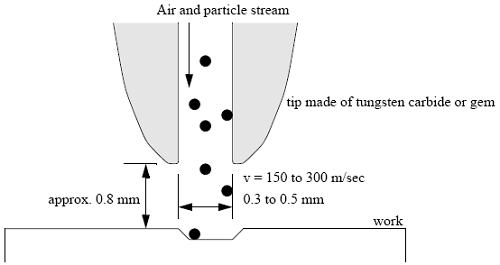

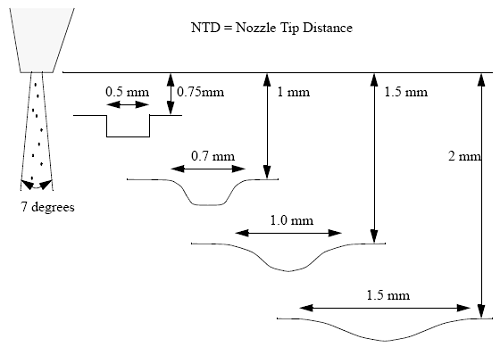

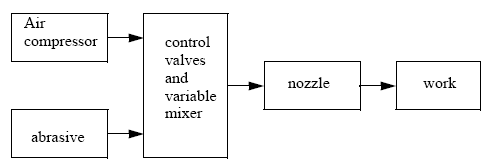

1. Fine particles (0.025mm) are accelerated in a gas stream (commonly air at a few times atmospheric pressure).

2. The particles are directed towards the focus of machining (less than 1mm from the tip).

3. As the particles impact the surface, they fracture off other particles.

As the particle impacts the surface, it causes a small fracture, and the gas stream carries both the abrasive particles and the fractured (wear) particles away.

Brittle and fragile work pieces work better.

Preview: Abrasive Water Jet Machining Material Rate Calculator

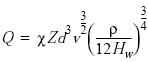

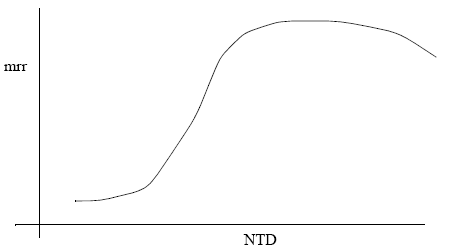

• Material Removal Rate (mrr) is,

Z = # of abrasive particles impacting per unit time (#/min),

d = mean diameter of abrasive grains (in),

v = velocity of abrasive grains (in/sec),

ρ = density of abrasive grains (lbs/in3),

Hw = the hardness of the workpiece - the flow stress (lbs/in2),

χ = a constant

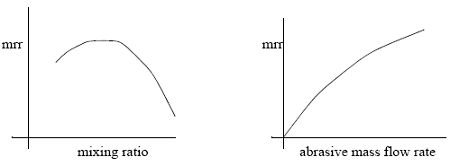

• Factors that effect the process are,

- mrr

- geometry of cut

- roughness of surface produced

- the rate of nozzle wear

• The factors are in turn effected by,

- the abrasive: composition; strength; size; mass flow rate

- the gas composition, pressure and velocity

- the nozzle: geometry; material; distance to work; inclination to work

• The abrasive,

- materials: aluminum oxide (preferred); silicon carbide

- the grains should have sharp edges

- material diameters of 10-50 micro m 15-20 is optimal

- should not be reused as the sharp edges are worn down and smaller particles can clog nozzle.

• Gas jet,

- mass flow rate of abrasive is proportional to gas pressure and gas flow

- pressure is typically 0.2 N/mm2 to 1 N/mm2

- gas composition effects pressure flow relationship

• Nozzle

- must be hard material to reduce wear by abrasives: WC (lasts 12 to 30 hr); sapphire (lasts 300 hr)

- cross sectional area of orifice is 0.05 - 0.2 mm2

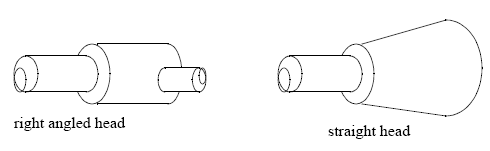

- orifice can be round or rectangular

- head can be straight, or at a right angle

• The relationship between head, and nozzle tip distance.

• Air drag also slows abrasive stream.

• Machines

Reference:

Ghosh, A., Manufacturing Science, Ellis Horwood Ltd., Chichester, UK, 1986.