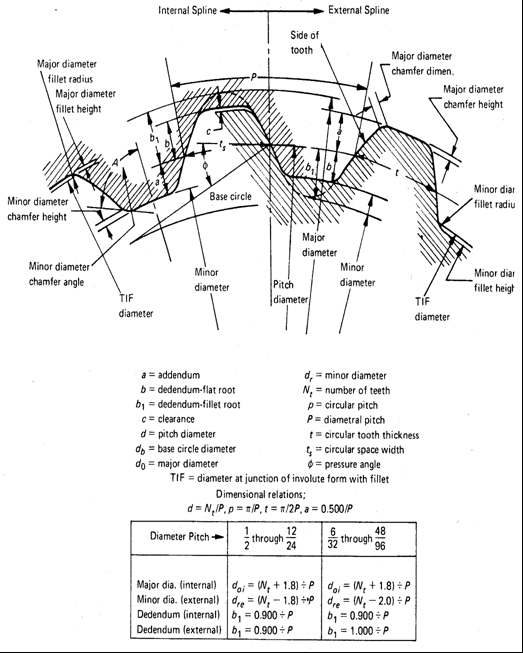

Involute Gear Design Equations and Calculator

|

The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. Notes:

Click on the image below to enlarge Related:

References: Deutschman, Michels, Wilson. Machine Design: Theory and Practice. Macmillan, 1975. Pp. 374-376. Link to this Webpage: © Copyright 2000 -

2024, by Engineers Edge, LLC |