Maximum Material Condition MMC vs Internal Feature Size Tolerance Chart Calculator

|

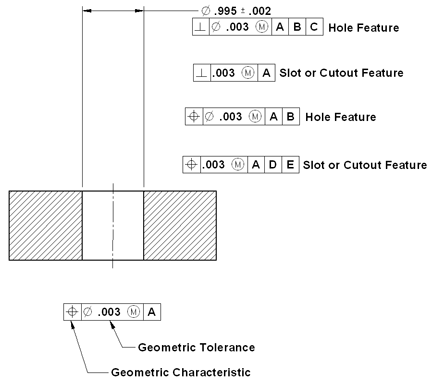

Tolerances, Engineering Design & Limits & Fits (This calculator requires a java - enabled browser) Internal feature of size Maximum Material Condition MMC Size Calculator. This calculator tool will create a Geometric Size vs MMC Maximum Material Condition Tolerance Chart per. ASME Y14.5-2018, ASME Y14.5-2009, ASME Y14.5M - 1994, or ISO 1101 Geometric Dimensioning and Tolerancing (GD&T). Related: External MMC vs Feature Size Tolerance Chart Tool Calculator

Where: MMC = Maximum Material Condition

Related Resources:

Link to this Webpage: © Copyright 2000 -

2024, by Engineers Edge, LLC |